The pots in smelting systems in which the metal is melted are operated with various voltages and currents. The supply is often unearthed. In most systems, the pots must be monitored separately to avoid shutting down the whole plant in the event of a fault. The EDS fault location system is an excellent option here. It quickly and automatically locates defective power circuits.

The power supply is decisively important when it comes to smelting systems. The medium voltage fed in is transformed down to 400 V in the transformer stations and fed to the system via cable bars or busbars and the low-voltage distribution board and sub-distribution boards. Bender ISOMETER®s or RCMS residual current monitoring systems monitor this and ensure continuous operation. Power quality drives are the perfect solution for monitoring the main and the sub-distribution boards.

| Name | Category | Size | Language | Timestamp | D-/B-Number |

|---|---|---|---|---|---|

| Power Quality/Measuring and monitoring relays | Product Overviews | 2.7 MB | EN | 2022/05/2525.05.2022 | |

| Product Overview ISOMETER®/ISOSCAN® | Product Overviews | 5.3 MB | EN | 2024/02/1616.02.2024 | |

| Insulation Fault Location - Planning and Setup | Technical article | 112.4 KB | EN | 2019/05/1313.05.2019 | |

| Electrical Safety in Control and Auxiliary Circuits | Technical article | 632.6 KB | EN | 2019/05/1313.05.2019 | |

| Electrical Safety in a Modern Nickel Smelting Plant | Technical article | 358.8 KB | EN | 2019/05/1313.05.2019 |

Products

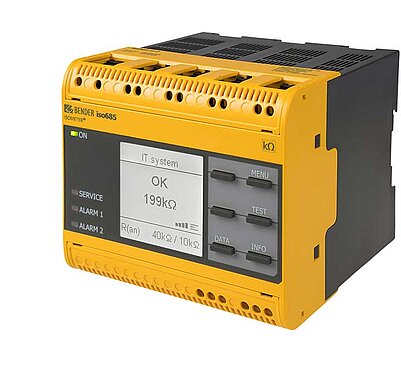

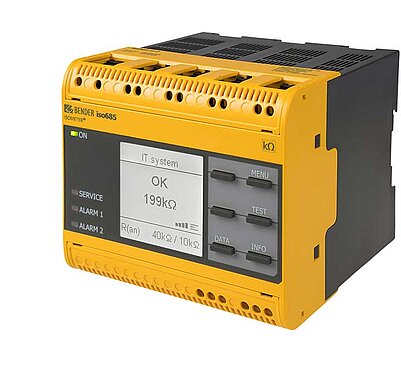

Insulation monitoring device for inverter applications and large industrial plants

![[Translate to English:] PEM353](/fileadmin/_processed_/b/a/csm_PEM353_WEB_list_649cf7fffd.jpg)

Universal measuring device with numerous measured quantities, energy and power measurement with storage, Power Quality Monitoring, limit value monitoring with alarm forwarding

Extension of the nominal voltage range of ISOMETER® iso685 series to AC 0...1150 V, DC 0...1760 V

Extension of the nominal voltage range of ISOMETER® iso685 series to AC, 3(N)AC 0...1650/0...1300 V

Extension of the nominal voltage range of ISOMETER® to AC 0...7200 V

The coupling device AGH675S-7/AGH675S-7MV15 is designed to extend the nominal voltage range of the ISOMETER® IRDH275BM-7 to AC/DC 0…15.5 kV.

Extension of the nominal voltage range of ISOMETER® iso685.../IR420-D64 series to AC 0...12 kV

Condition monitor with display and an integrated gateway

Recognising connections – optimising maintenance

![[Translate to English:] NGRM700](/fileadmin/_processed_/3/b/csm_NGRM700_01_WEB_list_97278228d7.jpg)

The advanced Neutral Grounding Resistor Monitor for sophisticated applications

Insulation monitoring device for inverter applications and large industrial plants

![[Translate to English:] PEM353](/fileadmin/_processed_/b/a/csm_PEM353_WEB_list_649cf7fffd.jpg)

Universal measuring device with numerous measured quantities, energy and power measurement with storage, Power Quality Monitoring, limit value monitoring with alarm forwarding

Extension of the nominal voltage range of ISOMETER® iso685 series to AC 0...1150 V, DC 0...1760 V

Extension of the nominal voltage range of ISOMETER® iso685 series to AC, 3(N)AC 0...1650/0...1300 V

Extension of the nominal voltage range of ISOMETER® to AC 0...7200 V

The coupling device AGH675S-7/AGH675S-7MV15 is designed to extend the nominal voltage range of the ISOMETER® IRDH275BM-7 to AC/DC 0…15.5 kV.

Extension of the nominal voltage range of ISOMETER® iso685.../IR420-D64 series to AC 0...12 kV

Condition monitor with display and an integrated gateway

Recognising connections – optimising maintenance

![[Translate to English:] NGRM700](/fileadmin/_processed_/3/b/csm_NGRM700_01_WEB_list_97278228d7.jpg)

The advanced Neutral Grounding Resistor Monitor for sophisticated applications

Electrical safety in low voltage distribution systems up to 1 000 v a.c. and 1 500 v d.c. - Equipment for testing, measuring or monitoring of protective measures - Part 8: Insulation monitoring devices for IT systems.

Electrical safety in low voltage distribution systems up to 1000 V a.c. and 1500 V d.c. - Equipment for testing, measuring or monitoring of protective measures - Part 9: Equipment for insulation fault location in IT systems

Electrical safety in low voltage distribution systems up to 1000 V ac and 1500 V dc - Equipment for testing, measuring or monitoring of protective measures - Part 15: Functional safety requirements for insulation monitoring devices in IT systems and equipment for insulation fault location in IT systems