Efficient, safe and environmentally-friendly extraction is incredibly important in the oil and gas industry. Of course, it involves dealing with combustible gases, liquids and vapours which go hand in hand with increased fire risk. This sets exacting standards for electrical safety, not only with respect to the production process. Pumps, conveyor belts and all drives are safely monitored by Bender RCMS residual current monitoring systems or ISOMETER®s. Insulation fault location devices are the right choice in order to solve problems quickly and efficiently.

In the separation facilities, which separate the raw material extracted into oil and gas, pumps with variable pressures which are controlled by frequency converters are often used. Although these frequency converters are very energy-saving to use, they also produce DC currents and harmonic vibrations which cannot be detected by normal fault current monitoring devices. The Bender systems offer reliable monitoring of these systems.

| Name | Category | Size | Language | Timestamp | D-/B-Number |

|---|---|---|---|---|---|

| Product Overview ISOMETER®/ISOSCAN® | Product Overviews | 5.3 MB | EN | 2024/02/1616.02.2024 | |

| Product Overview - Residual Current Monitoring | Product Overviews | 4.2 MB | EN | 2026/02/1111.02.2026 | |

| Insulation Fault Location - Planning and Setup | Technical article | 112.4 KB | EN | 2019/05/1313.05.2019 | |

| Electrical Safety in Control and Auxiliary Circuits | Technical article | 632.6 KB | EN | 2019/05/1313.05.2019 | |

| Stationary Insulation Fault Location System in Drill Rigs | Technical article | 114.8 KB | EN | 2019/05/1313.05.2019 | |

| Stationary Insulation Fault Location System in Drill Rigs | Technical article | 114.8 KB | EN | 2023/04/2121.04.2023 | |

| Electrical Safety in Control and Auxiliary Circuits | Technical article | 632.6 KB | EN | 2023/04/2121.04.2023 |

Products

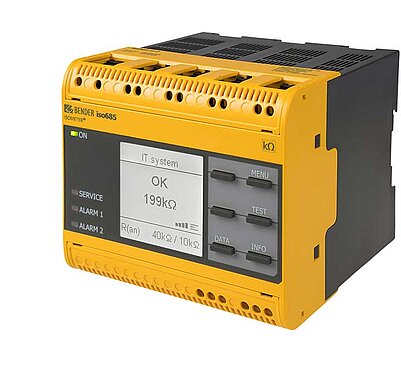

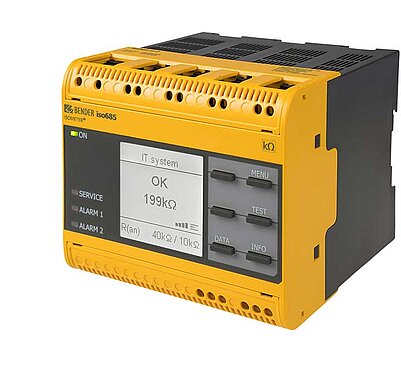

Insulation monitoring device for inverter applications and large industrial plants

Insulation monitoring device for measuring high-resistance insulation resistances up to 10 GΩ and to monitor long parallel cable

Extension of the nominal voltage range of ISOMETER® iso685 series to AC 0...1150 V, DC 0...1760 V

Extension of the nominal voltage range of ISOMETER® iso685 series to AC, 3(N)AC 0...1650/0...1300 V

Extension of the nominal voltage range of ISOMETER® to AC 0...7200 V

Multichannel AC, pulsed DC and AC/DC sensitive residual current monitor

Multichannel AC, pulsed DC and AC/DC sensitive residual current monitor

Multichannel AC, pulsed DC and AC/DC sensitive residual current monitor with one alarm contact per channel

Multichannel AC, pulsed DC and AC/DC sensitive residual current monitor with one alarm contact per channel

Insulation monitoring device for inverter applications and large industrial plants

Insulation monitoring device for measuring high-resistance insulation resistances up to 10 GΩ and to monitor long parallel cable

Extension of the nominal voltage range of ISOMETER® iso685 series to AC 0...1150 V, DC 0...1760 V

Extension of the nominal voltage range of ISOMETER® iso685 series to AC, 3(N)AC 0...1650/0...1300 V

Extension of the nominal voltage range of ISOMETER® to AC 0...7200 V

Multichannel AC, pulsed DC and AC/DC sensitive residual current monitor

Multichannel AC, pulsed DC and AC/DC sensitive residual current monitor

Multichannel AC, pulsed DC and AC/DC sensitive residual current monitor with one alarm contact per channel

Multichannel AC, pulsed DC and AC/DC sensitive residual current monitor with one alarm contact per channel

Electrical safety in low voltage distribution systems up to 1 000 v a.c. and 1 500 v d.c. - Equipment for testing, measuring or monitoring of protective measures - Part 8: Insulation monitoring devices for IT systems.

Electrical safety in low voltage distribution systems up to 1000 V a.c. and 1500 V d.c. - Equipment for testing, measuring or monitoring of protective measures - Part 9: Equipment for insulation fault location in IT systems

Electrical safety in low voltage distribution systems up to 1000 V ac and 1500 V dc - Equipment for testing, measuring or monitoring of protective measures - Part 15: Functional safety requirements for insulation monitoring devices in IT systems and equipment for insulation fault location in IT systems

Electronic equipment for use in power installations