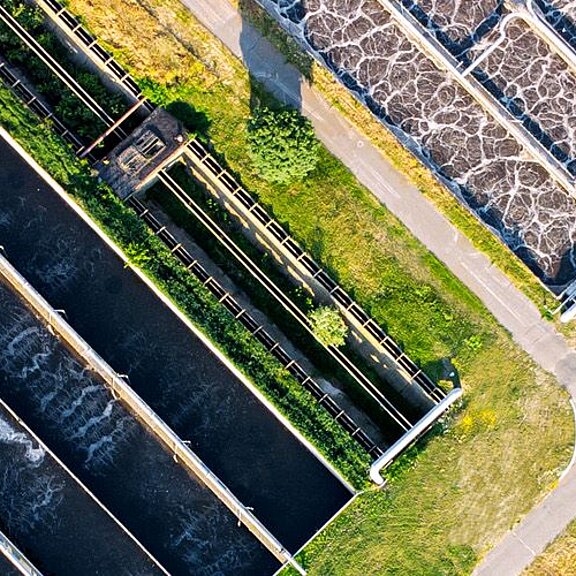

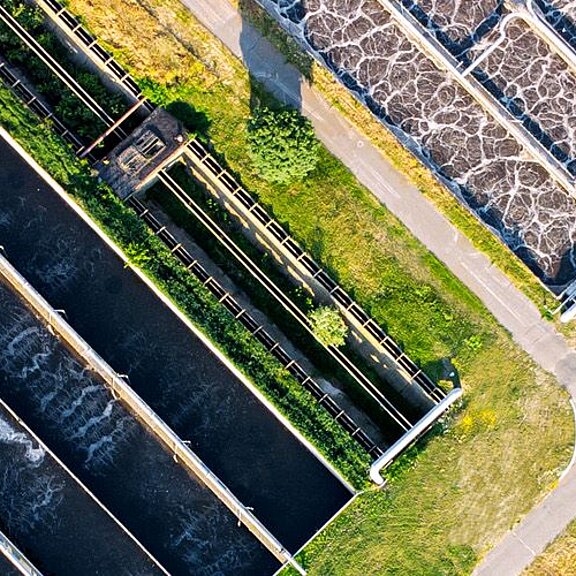

As part of the critical infrastructure, water and wastewater treatment plants have to run 24/7. There must be no failures. Failures and shutdowns are usually caused by insulation faults in pumps, drives, motors or their supply lines.

Such failures can be prevented with the right monitoring technology. Planned shutdowns for recurring inspections can also be avoided.

Read on to find out what solutions Bender has in store for you to keep your waterworks and wastewater treatment plant running without interruption.

Insulation monitoring devices are used in unearthed systems to detect insulation faults.

Applications

Pumps, drives, agitators, valves, aerators, flow meters

Benefits

Residual current monitoring devices are used to detect insulation faults in earthed systems.

Applications

Pumps, drives, agitators, valves, aerators, flow meters

Benefits

Consumers that are only used very rarely can be monitored with special offline monitors.

Applications

Emergency slide valves and other important consumers that are usually switched off

Benefits

The Süderdithmarschen Water Association near Hamburg (Germany) has been monitoring its waterworks and wastewater treatment plants since 2023 to ensure 24/7 operation and reduce the cost of periodic inspections.

Would you like to protect your waterworks or sewage treatment plant from failures? Our experts will be happy to advise you – personally and without obligation.

TO CONTACT FORMHow you avoid downtimes of electrical systems with residual current monitoring

Advantages and benefits of resiual current monitoring.

The technology in brief and why there are different devices for different applications.