Residual current monitoring for waterworks and sewage treatment plants

Waterworks and sewage treatment plants must operate 24/7/365. Operational interruptions are undesirable, as otherwise the supply of fresh drinking water to the population and the disposal of wastewater cannot be guaranteed 100%.

However, the damp or wet environment in waterworks and sewage treatment plants poses a real challenge for the operation of numerous electrical consumers. This is because moisture or wetness, as well as ageing of materials, can cause fault currents that lead to consumers being shut down. Residual current monitoring allows such fault currents to be detected at an early stage before shutdowns occur.

Read here why, as an operator of waterworks and sewage treatment plants, you should monitor your electrical consumers using residual current measurement technology if you want to ensure 24/7 operation.

Residual current monitoring explained briefly

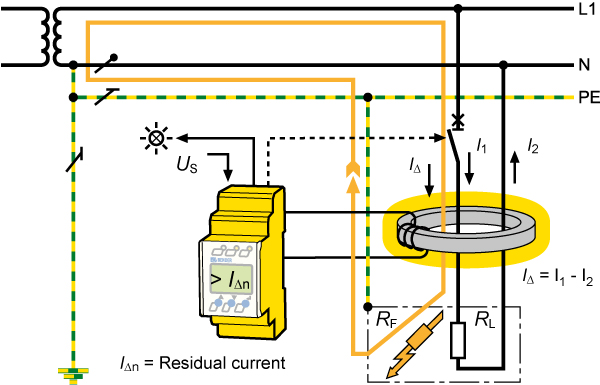

Residual current monitoring is a technology capable of detecting fault currents in earthed power grids/electrical systems. Normally, in an electrical circuit, the sum of the currents flowing into the electrical consumers and the currents flowing out of the consumers is equal. This means there is no residual current. If a fault current flows through earth (PE) in an electrical circuit, e.g. due to faulty insulation of a cable or moisture penetrating a drive, the incoming and outgoing currents are of different magnitudes. This residual current is detected by a measuring current transformer and transmitted to the evaluation device. If a specified limit value is exceeded, the measuring device alerts the operator.

Application in waterworks and sewage treatment plants

Waterworks and sewage treatment plants use numerous electrical consumers such as pumps and drives. Moisture or wetness getting in can cause fault currents in the supply lines or the consumers themselves, which can lead to pumps, drives or entire areas being shut down. Even a fault current of 30 mA will trip an RCD (residual current circuit breaker).

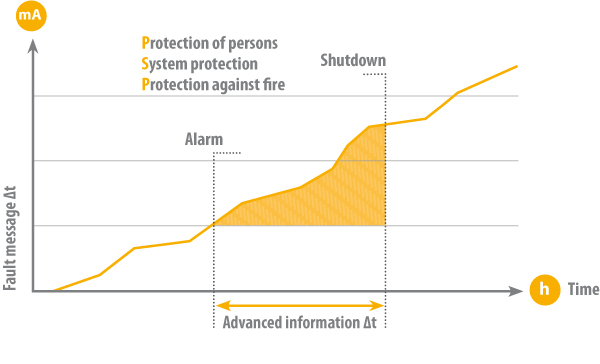

Since most of these fault currents do not occur spontaneously but are initially very small, they can be detected using residual current monitoring devices before the critical threshold of 30 mA is reached and the RCD trips. The monitoring devices are set to sound an alarm as soon as a specified limit value is exceeded.

This way, technical staff are informed of an electrical fault at an early stage, before the RCD trips.

Advantages of residual current monitoring

The monitoring of electrical consumers using residual current measurement technology is continuous, i.e. 24/7/365. This means that operators always know the status of their electrical systems and consumers. If an error occurs, it is reported early on, long before the RCD shuts down individual consumers or entire system components.

Here is an overview of the advantages:

- Permanent monitoring 24/7/365

- Early detection of electrical faults, including alarm notification

- Avoiding spontaneous shutdown by RCD

Conclusion

If waterworks and sewage treatment plants are to operate without interruption, the use of suitable monitoring technology is essential. Residual current measurement technology is the method of choice here. Residual current measurement technology is the method of choice here. This is because it is able to detect faults in electrical consumers and supply lines at an early stage and prevent spontaneous shutdowns.

Do you have any questions? Get in touch with us.