Operational safety of waterworks

Modern measurement technology for 24/7 operation of water and wastewater treatment plants

There are over 5,700 water supply companies and around 5,100 sewage treatment plants in Germany. Their task is to supply the approximately 82 million inhabitants of Germany with clean drinking water and at the same time to dispose of and purify the wastewater.

Read in this article how modern measurement technology ensures the 24/7 operation of water and wastewater treatment plants and avoids unplanned outages.

Failures not desired

Water and sewage treatment plants are part of the critical infrastructure. Their services must be available 24 hours a day, 7 days a week. To ensure that the water supply and wastewater disposal function smoothly, many electrical consumers are also required, for example pumps, drives for aerators, agitators, propulsion drives, valves and flow meters.

These electrical consumers are exposed to various environmental influences. Depending on the place of use, this includes above all moisture and wetness, but also temperature fluctuations due to the weather. If one of the electrical consumers fails, for example due to water ingress, this can lead to unwanted interruptions in the water supply or wastewater disposal.

However, such spontaneous and unplanned outages are just one of many problems that operators of waterworks and sewage treatment plants have to face.

Periodic inspection in accordance with German DGUV regulation 3 impairs 24/7 operation

All electrical consumers and systems must be regularly checked for safety. The main purpose of these tests is to prevent accidents caused by electric shock and damage to the system.

However, the periodic inspections in accordance with German DGUV Regulation 3 pose several major challenges for operators of waterworks and wastewater treatment plants. For one thing, the periodic inspection is time-consuming and labour-intensive. Secondly, the electrical systems or system components must be switched off and disconnected from the power supply for the measurement of the RISO insulation resistance. This means that 24/7 operation of pumps, drives or agitators is not possible.

The good news: There are ways to avoid unplanned breakdowns and shutdowns and at the same time significantly reduce the cost of periodic inspections in accordance with DGUV Regulation 3.

Continuous monitoring of electrical systems enables 24/7 operation

Spontaneous failures of electrical consumers and systems are usually caused by residual currents. These are caused, for example, by deteriorating insulation, material fatigue and penetrating moisture. If the residual current in an electrical system or load rises to the critical value of 30 mA, the residual current circuit breaker (RCD) switches off the system. If the residual current is below the critical value of 30 mA, the RCD does not yet trip. With suitable measurement technology, such fault currents, which are usually harbingers of a shutdown, can be detected.

In earthed networks, residual current measurement technology is the method of choice here. It constantly checks electrical systems for residual currents and alerts the technical staff as soon as a residual current occurs. Early alarms enable technical personnel to react in good time and prevent impending system component failures. This enables 24/7 operation of waterworks and wastewater treatment plants.

Planned shutdowns for the periodic inspection in accordance with DGUV regulation 3 can also be dispensed with by using residual current monitoring. The continuous measurement of electrical systems for residual currents replaces the time-consuming measurement of RISO insulation resistance. This means that parts of the system no longer need to be switched off and disconnected from the power supply for the test and the time and effort required for the test is significantly reduced.*

Read here how Wasserverband Süderdithmarschen avoids shutdowns for periodic inspections in accordance with DGUV Regulation 3.

Advantages of permanent monitoring of electrical systems at a glance

The use of modern measurement technology for monitoring electrical systems pays off for water and wastewater treatment plants. These are the advantages:

1. Reliability

Full transparency regarding the status of the electrical installation at all times

Easy detection of faults and malfunctions

Simplified troubleshooting in the event of malfunctions or failures

2. Periodic inspection in accordance with DGUV Regulation 3

Permanent monitoring for insulation faults/fault currents instead of checking every four years

No switching off and disconnecting of systems or system components for RISO measurement

Less time and manpower required

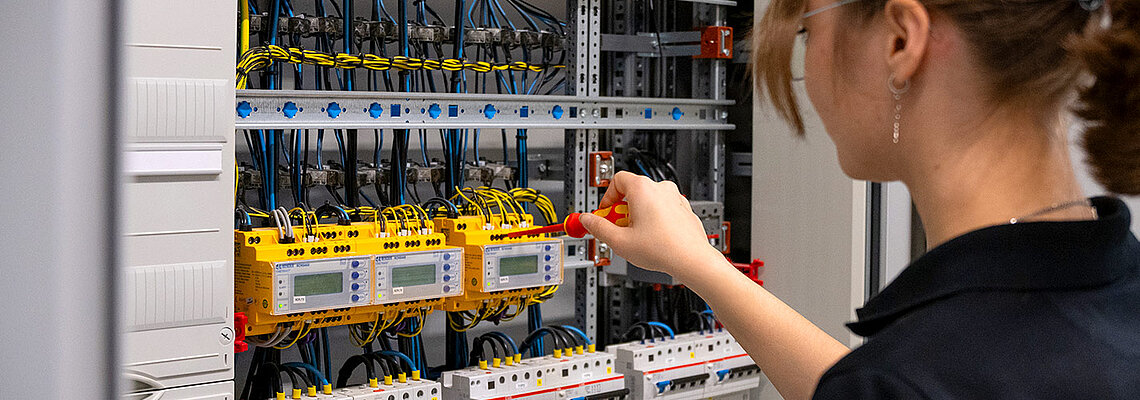

Measurement technology from Bender ensures 24/7 operation

Unplanned downtimes or planned shutdowns for the periodic inspection in accordance with DGUV Regulation 3 do not have to happen. Residual current measurement technology from Bender can be used to detect residual currents in electrical systems and loads before they cause the RCD to switch off. In addition, permanent monitoring considerably simplifies periodic testing in accordance with DGUV regulation 3, as it is no longer necessary to switch off and disconnect electrical loads or system components.

Read here what other options there are for operating water works 24/7.